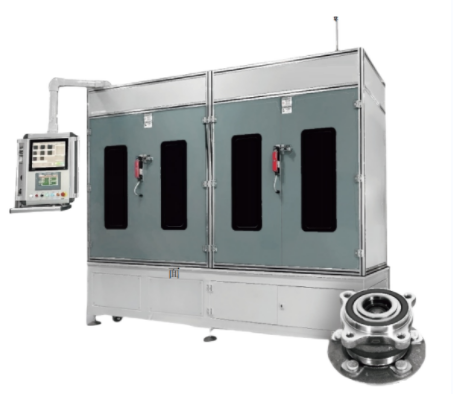

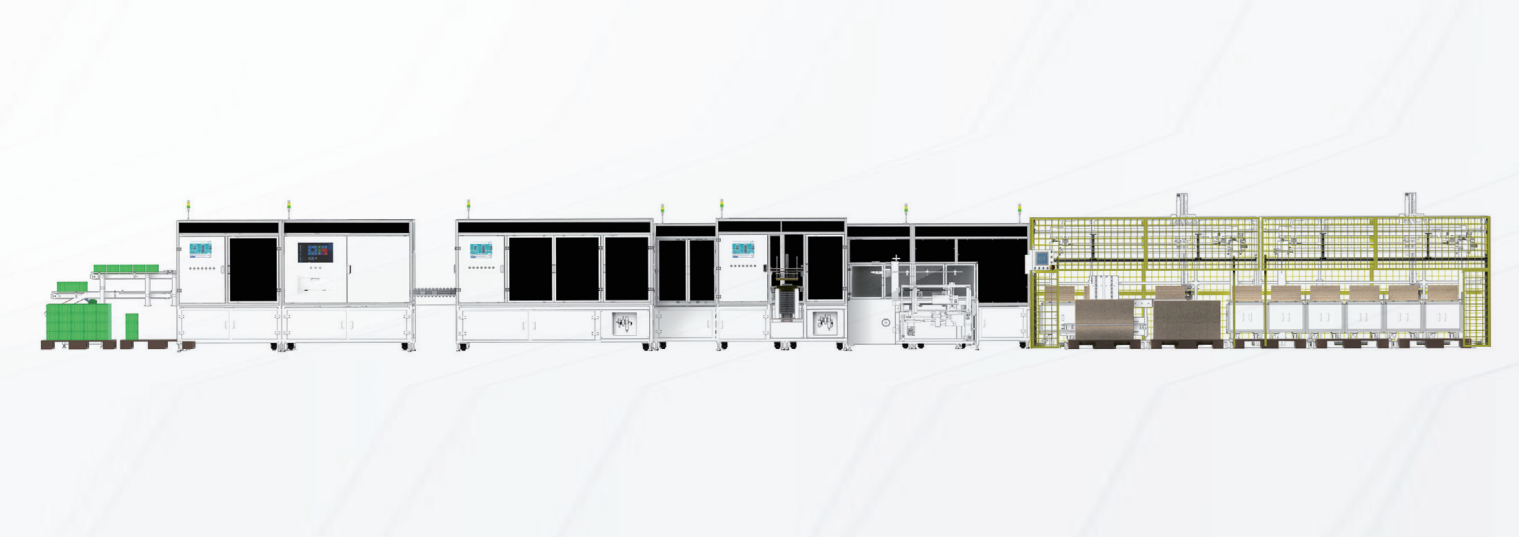

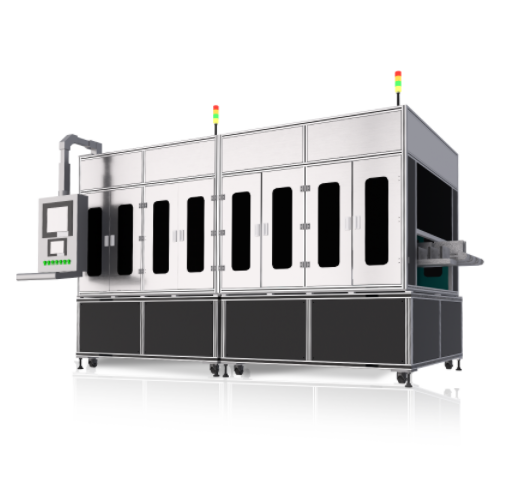

AOI MACHINE FOR Wheel Hub Bearing Appearance Defects

The first visual inspection equipment designed for the third generation of hub bearings can realize the online full inspection of all visible defects of hub bearings.It adopts the multi-angle and multi-station imaging method,which solves the complex difficulties in the detection of abnormal parts,while maintaining a high detection speed.The equipment has traditional algorithms and machine learning (Al) algorithms, which can accurately detect various types of defects and minimize the misjudgment rate.As the final inspection link of the automated production line,it greatly reduces the manual participation and helps manufacturers improve the quality stability of products.

Machine Vision

Machine Vision Bearing

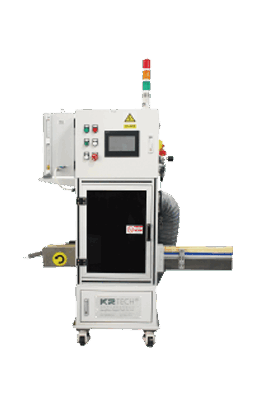

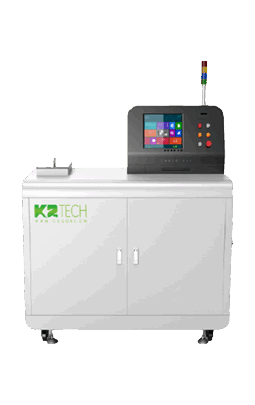

Bearing AOI Machine for Roller Appearance Defects(Choyo-R41) AOI Machine for Needle Roller Appearance Defects(Choyo-R21) AOI Robot for Big Roller Appearance Defects AOI Robot for SRB Bearings Appearance Defects AOI Robot for Big Roller Appearance Defects AOI MACHINE FOR Wheel Hub Bearing Appearance Defects AOI Machine for Bearing Ring Appearance Defects AOI Machine for Sealing Ring Appearance Defects AOI Machine for Bearing Dust Shield Appearance Defects AOI Machine for Bearing Appearance Defects Automatic Feeding Machine for Bearing Rollers Automatic Oiling Machine for Bearing Rollers Automatic Washing & Drying Machine for Bearing Rollers AOI ROBOT FOR BALL BEARING APPEARANCE DEFECTS

AOI Machine for Roller Appearance Defects(Choyo-R41) AOI Machine for Needle Roller Appearance Defects(Choyo-R21) AOI Robot for Big Roller Appearance Defects AOI Robot for SRB Bearings Appearance Defects AOI Robot for Big Roller Appearance Defects AOI MACHINE FOR Wheel Hub Bearing Appearance Defects AOI Machine for Bearing Ring Appearance Defects AOI Machine for Sealing Ring Appearance Defects AOI Machine for Bearing Dust Shield Appearance Defects AOI Machine for Bearing Appearance Defects Automatic Feeding Machine for Bearing Rollers Automatic Oiling Machine for Bearing Rollers Automatic Washing & Drying Machine for Bearing Rollers AOI ROBOT FOR BALL BEARING APPEARANCE DEFECTS