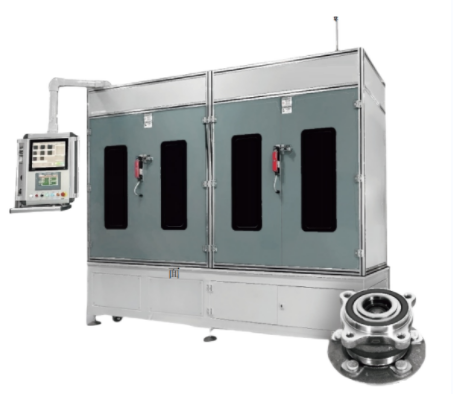

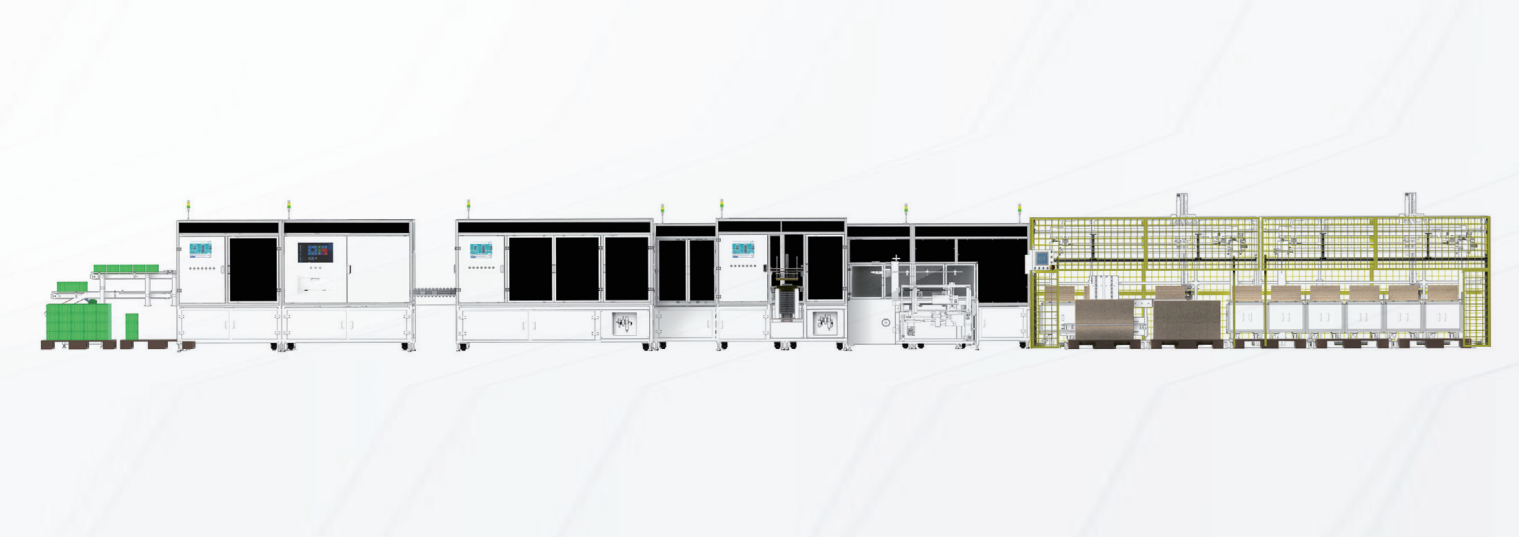

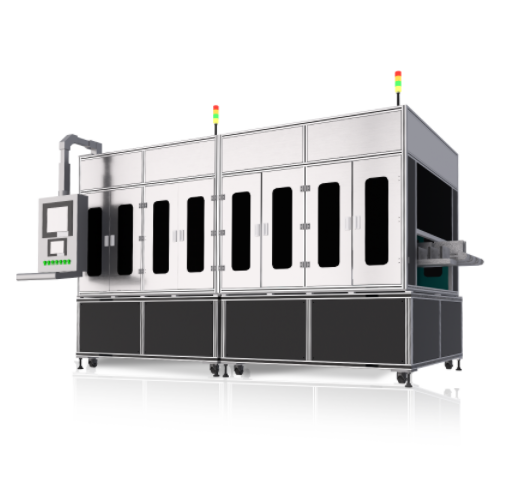

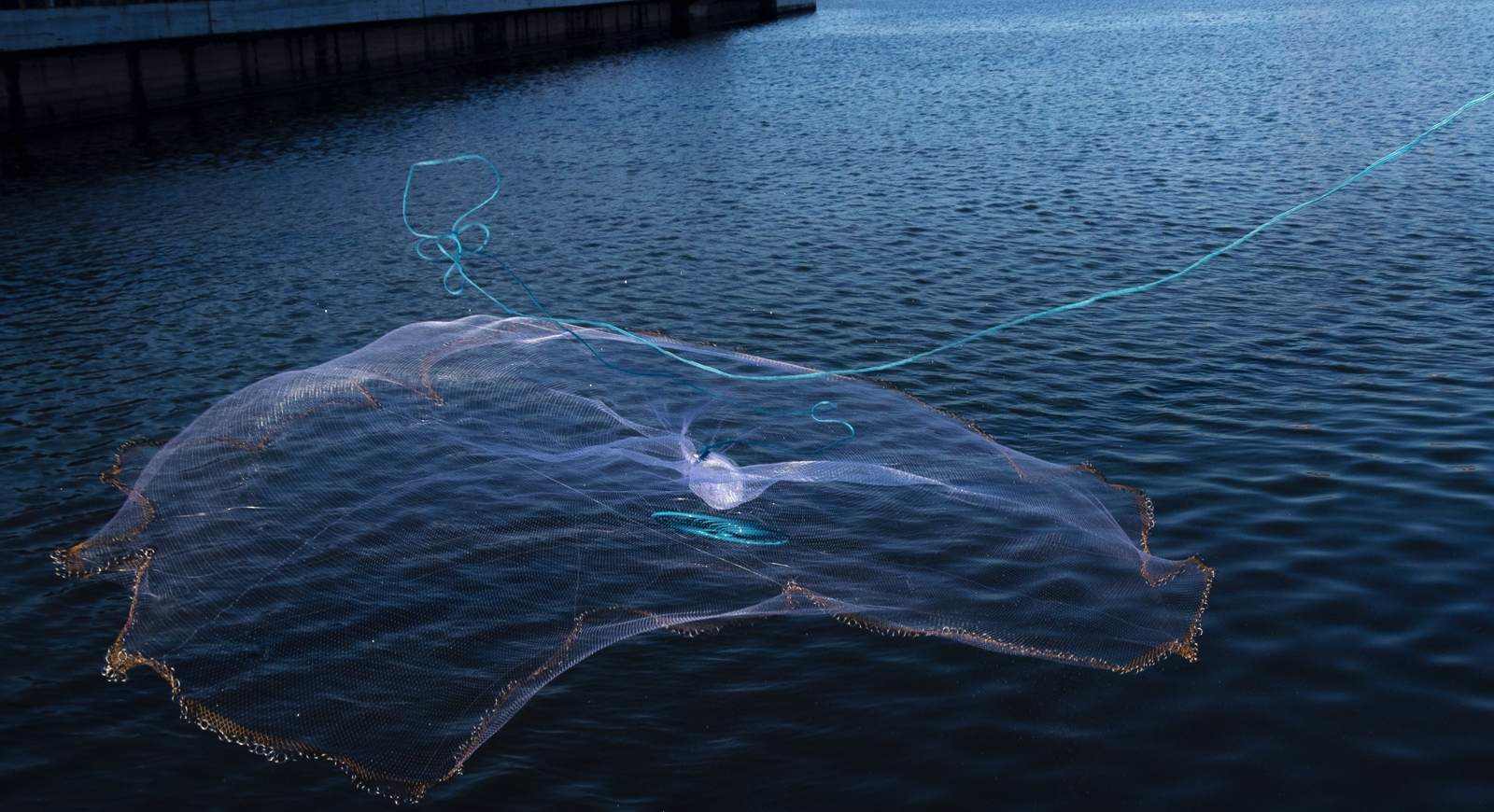

Automatic Washing & Drying Machine for Bearing Rollers

This machine can be connected with the roller super-finishing machine at the front end and the automatic optical inspection machine at the back end. The speed reaches to 12000pcs/h with no secondary damage. It can be used to all kinds of water and oil cleaning detergent, no water logging after cleaning. It’s easy to operate to change models with wide range of compatible size. It can help customers to accomplish product in line, save labor cost, avoid the problem of secondary damage caused by the transmitting, and improve the quality and enhance the product competitiveness.

Machine Vision

Machine Vision Bearing

Bearing AOI Machine for Roller Appearance Defects(Choyo-R41) AOI Machine for Needle Roller Appearance Defects(Choyo-R21) AOI Robot for Big Roller Appearance Defects AOI Robot for SRB Bearings Appearance Defects AOI Robot for Big Roller Appearance Defects AOI MACHINE FOR Wheel Hub Bearing Appearance Defects AOI Machine for Bearing Ring Appearance Defects AOI Machine for Sealing Ring Appearance Defects AOI Machine for Bearing Dust Shield Appearance Defects AOI Machine for Bearing Appearance Defects Automatic Feeding Machine for Bearing Rollers Automatic Oiling Machine for Bearing Rollers Automatic Washing & Drying Machine for Bearing Rollers AOI ROBOT FOR BALL BEARING APPEARANCE DEFECTS

AOI Machine for Roller Appearance Defects(Choyo-R41) AOI Machine for Needle Roller Appearance Defects(Choyo-R21) AOI Robot for Big Roller Appearance Defects AOI Robot for SRB Bearings Appearance Defects AOI Robot for Big Roller Appearance Defects AOI MACHINE FOR Wheel Hub Bearing Appearance Defects AOI Machine for Bearing Ring Appearance Defects AOI Machine for Sealing Ring Appearance Defects AOI Machine for Bearing Dust Shield Appearance Defects AOI Machine for Bearing Appearance Defects Automatic Feeding Machine for Bearing Rollers Automatic Oiling Machine for Bearing Rollers Automatic Washing & Drying Machine for Bearing Rollers AOI ROBOT FOR BALL BEARING APPEARANCE DEFECTS